YG型 不锈钢立式离心油泵

产品简介

详细信息

不锈钢立式离心油泵特点:

1、泵为立式结构,进出口口径相同,且位于同一中心线上,可像阀门一样安装于管路之中,外形紧凑美观,占地面积小,建筑投入低,户外型电机可置于户外使用。

2、叶轮直接安在电机的加长轴上,轴向尺寸短,结构紧凑,泵与电机轴承配置合理.能有效地平衡泵运转产生的径向和轴向自荷,从而保证了泵的运行平稳,振动噪音很低。

3、轴封采用机械密封或机械密封组合,采用进口钛合金密封环、中型耐高温机械密封和采用硬质合金材质,耐磨密封,能有效地增长机械密封的使用寿命。轴端无泄漏,有效地减少了泵房的油气含量,改善了工作环境,提高泵高工作的安全可靠性。

4、安装检修方便,无需拆动管路系统,只要卸下泵联体座螺母即可抽出全部转子部件。

5、可根据使用要求即流量和扬程的需要采用泵的串、并联运行方式。

6、可根据管路布置的要求采用泵的竖式和横式安装。

7、YG型管道油泵叶轮都是采用优质铜叶轮,具有很好的防静电和无污染特点。

8、电动机采购上海防爆电机厂家选用防爆等级为dIIBT4的EX防爆电动机,具有优良的防爆性能,可以安全放心的输送可燃液体和隔爆区使用。

9、关键零部件选用优质新型材料,根据输送介质的腐蚀性和温度要求,提高了泵的工作可靠性和使用寿命。

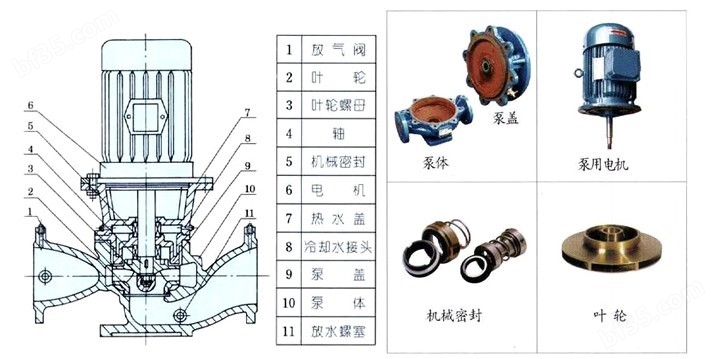

不锈钢立式离心油泵结构图:

不锈钢立式离心油泵主要用途:

1.YG型立式管道油泵,供输送汽油、煤油、柴油等石油产品,被输送介质温度为-20℃-+120℃。

2.该泵主要使用在管路增压,远距离输送汽油、煤油、柴油等油类,也可输送其它无腐蚀性的液体。 适用于油库、油站、化工、矿山、石化、企事业单位等。

YG不锈钢管道油泵性能参数:

| 型 号 | 流 量Q | 扬程 m | 效率 % | 转速 r/min | 电机功率 KW | 允许汽蚀余量 m | |

| m3/h | l/s | ||||||

| YG15-80 | 1.5 | 0.42 | 8 | 34 | 2800 | 0.18 | 2.3 |

| YG20-110 | 2.5 | 0.69 | 15 | 34 | 2800 | 0.37 | 2.3 |

| YG20-160 | 2.5 | 0.69 | 32 | 25 | 2900 | 0.75 | 2.3 |

| YG25-110 | 4 | 1.11 | 15 | 42 | 2900 | 0.55 | 2.3 |

| YG25-125 | 4 | 1.11 | 20 | 36 | 2900 | 0.75 | 2.3 |

| YG25-125A | 3.6 | 1.0 | 16 | 35 | 2900 | 0.55 | 2.3 |

| YG25-160 | 4 | 1.11 | 32 | 32 | 2900 | 1.5 | 2.3 |

| YG25-160A | 3.7 | 1.03 | 28 | 31 | 2900 | 1.1 | 2.3 |

| YG32-100 | 4.5 | 12.5 | 12.5 | 44 | 2900 | 0.55 | 2.3 |

| YG32-100(I) | 6.3 | 1.75 | 12.5 | 54 | 2900 | 0.75 | 2.3 |

| YG32-125 | 5 | 1.39 | 20 | 44 | 2900 | 0.75 | 2.3 |

| YG32-125A | 4.5 | 1.25 | 16 | 43 | 2900 | 0.55 | 2.3 |

| YG32-160 | 6.5 | 5 | 32 | 44 | 2900 | 1.5 | 2.3 |

| YG32-160A | 4 | 1.1 | 25 | 34 | 2900 | 1.1 | 2.0 |

| YG32-160(I) | 6.3 | 1.75 | 32 | 40 | 2900 | 2.2 | 2.0 |

| YG32-200 | 4.5 | 12.5 | 50 | 32 | 2900 | 3 | 2.0 |

| YG32-200(I) | 6.3 | 1.75 | 50 | 33 | 2900 | 4 | 2.0 |

| YG32-200A | 4 | 1.11 | 44 | 40 | 2900 | 2.2 | 2.0 |

| YG40-100 | 6.3 | 1.75 | 12.5 | 54 | 2900 | 0.55 | 2.3 |

| YG40-100A | 5.6 | 1.56 | 10 | 52 | 2900 | 0.37 | 2.3 |

| YG40-125 | 6.3 | 1.75 | 20 | 46 | 2900 | 1.1 | 2.3 |

| YG40-125A | 5.6 | 1.56 | 16 | 45 | 2900 | 0.75 | 2.3 |

| YG40-160 | 6.3 | 1.75 | 32 | 40 | 2900 | 2.2 | 2.3 |

| YG40-160A | 5.9 | 1.64 | 28 | 39 | 2900 | 1.5 | 2.3 |

| YG40-160B | 5.5 | 1.53 | 24 | 38 | 2900 | 1.1 | 2.3 |

| YG40-200 | 6.3 | 1.75 | 50 | 33 | 2900 | 4 | 2.3 |

| YG40-200A | 5.9 | 1.64 | 44 | 31 | 2900 | 3 | 2.3 |

| YG40-200B | 5.3 | 1.47 | 36 | 29 | 2900 | 2.2 | 2.3 |

| YG40-250 | 6.3 | 1.75 | 80 | 28 | 2900 | 7.5 | 2.3 |

| YG40-250A | 5.9 | 1.64 | 70 | 28 | 2900 | 5.5 | 2.3 |

| YG40-250B | 5.5 | 1.53 | 60 | 27 | 2900 | 4 | 2.3 |

| YG40-100(I) | 12.5 | 3.47 | 12.5 | 62 | 2900 | 1.1 | 2.3 |

| YG40-100(I)A | 11 | 3.05 | 10 | 60 | 2900 | 0.75 | 2.3 |

| YG40-125(I) | 12.5 | 3.47 | 20 | 58 | 2900 | 1.5 | 2.3 |

| YG40-125(I)A | 11 | 3.05 | 16 | 57 | 2900 | 1.1 | 2.3 |

| YG40-160(I) | 12.5 | 3.47 | 32 | 52 | 2900 | 3 | 2.3 |

| YG40-160(I)A | 11.7 | 3.25 | 28 | 51 | 2900 | 2.2 | 2.3 |

| YG40-160(I)B | 10.4 | 2.89 | 22 | 50 | 2900 | 1.5 | 2.3 |

| YG40-200(I) | 12.5 | 3.47 | 50 | 46 | 2900 | 5.5 | 2.3 |

| YG40-200(I)A | 11.7 | 3.25 | 44 | 45 | 2900 | 4 | 2.3 |

| YG40-200(I)B | 10.6 | 2.94 | 36 | 44 | 2900 | 3 | 2.3 |

| YG40-250(I) | 12.5 | 3.47 | 80 | 38 | 2900 | 11 | 2.3 |

| YG40-250(I)A | 11.6 | 3.22 | 70 | 38 | 2900 | 7.5 | 2.3 |

| YG40-250(I)B | 10.8 | 3.0 | 60 | 37 | 2900 | 7.5 | 2.3 |

| YG40-250(I)C | 10.0 | 2.78 | 52 | 36 | 2900 | 5.5 | 2.3 |

| YG50-100 | 12.5 | 3.47 | 12.5 | 62 | 2900 | 1.1 | 2.3 |

| YG50-100A | 11 | 3.05 | 10 | 60 | 2900 | 0.75 | 2.3 |

| YG50-125 | 12.5 | 3.47 | 20 | 58 | 2900 | 1.5 | 2.3 |

| 型 号 | 流 量Q | 扬程 m | 效率 % | 转速 r/min | 电机功率 KW | 允许汽蚀余量 m | |

| m3/h | l/s | ||||||

| YG50-125A | 11 | 3.05 | 16 | 57 | 2900 | 1.1 | 2.3 |

| YG50-160 | 12.5 | 3.47 | 32 | 52 | 2900 | 3 | 2.3 |

| YG50-160A | 11.7 | 3.25 | 28 | 51 | 2900 | 2.2 | 2.3 |

| YG50-160B | 10.4 | 2.89 | 22 | 50 | 2900 | 1.5 | 2.3 |

| YG50-200 | 12.5 | 3.47 | 50 | 46 | 2900 | 5.5 | 2.3 |

| YG50-200A | 11.7 | 3.25 | 44 | 45 | 2900 | 4 | 2.3 |

| YG50-200B | 10.6 | 2.94 | 36 | 44 | 2900 | 3 | 2.3 |

| YG50-250 | 12.5 | 3.47 | 80 | 38 | 2900 | 11 | 2.3 |

| YG50-250A | 11.6 | 3.22 | 70 | 38 | 2900 | 7.5 | 2.3 |

| YG50-250B | 10.8 | 3.0 | 60 | 37 | 2900 | 7.5 | 2.3 |

| YG50-250C | 10.0 | 2.78 | 52 | 36 | 2900 | 5.5 | 2.3 |

| YG50-100(I) | 25 | 6.94 | 12.5 | 69 | 2900 | 1.5 | 2.5 |

| YG50-100(I)A | 22.3 | 6.19 | 10 | 67 | 2900 | 1.1 | 2.5 |

| YG50-125(I) | 25 | 6.94 | 20 | 68 | 2900 | 3 | 2.5 |

| YG50-125(I)A | 22.3 | 6.19 | 16 | 66 | 2900 | 2.2 | 2.5 |

| YG50-160(I) | 25 | 6.94 | 32 | 63 | 2900 | 4 | 2.5 |

| YG50-160(I)A | 23.4 | 6.5 | 28 | 62 | 2900 | 4 | 2.5 |

| 50-160(I)B | 21.6 | 6.0 | 24 | 58 | 2900 | 3 | 2.5 |

| YG50-200(I) | 25 | 6.94 | 50 | 58 | 2900 | 7.5 | 2.5 |

| YG50-200(I)A | 23.5 | 6.53 | 44 | 57 | 2900 | 7.5 | 2.5 |

| YG50-200(I)B | 21.8 | 6.06 | 38 | 55 | 2900 | 5.5 | 2.5 |

| YG50-250(I) | 25 | 6.94 | 80 | 50 | 2900 | 15 | 2.5 |

| YG50-250(I)A | 23.4 | 6.5 | 70 | 50 | 2900 | 11 | 2.5 |

| YG50-250(I)B | 21.6 | 6.0 | 60 | 49 | 2900 | 11 | 2.5 |

| YG50-315(I) | 25 | 6.94 | 125 | 40 | 2900 | 30 | 2.5 |

| 50-315(I)A | 23.7 | 6.58 | 113 | 40 | 2900 | 22 | 2.5 |

| YG50-315(I)B | 22.5 | 6.25 | 101 | 39 | 2900 | 18.5 | 2.5 |

| YG50-315(I)C | 20.6 | 5.72 | 85 | 38 | 2900 | 15 | 2.5 |

| YG65-100 | 25 | 6.94 | 12.5 | 69 | 2900 | 1.5 | 2.5 |

| YG65-100A | 22.3 | 6.19 | 10 | 67 | 2900 | 1.1 | 2.5 |

| YG65-125 | 25 | 6.94 | 20 | 68 | 2900 | 3 | 2.5 |

| YG65-125A | 22.3 | 6.19 | 16 | 66 | 2900 | 2.2 | 2.5 |

| YG65-160 | 25 | 6.94 | 32 | 63 | 2900 | 4 | 2.5 |

| YG65-160A | 23.4 | 6.5 | 28 | 62 | 2900 | 4 | 2.5 |

| YG65-160B | 21.6 | 6.0 | 24 | 58 | 2900 | 3 | 2.5 |

| YG65-200 | 25 | 6.94 | 50 | 58 | 2900 | 7.5 | 2.5 |

| YG65-200A | 23.5 | 6.53 | 44 | 57 | 2900 | 7.5 | 2.5 |

| YG65-200B | 21.8 | 6.06 | 38 | 55 | 2900 | 5.5 | 2.5 |

| YG65-250 | 25 | 6.94 | 80 | 50 | 2900 | 15 | 2.5 |

| YG65-250A | 23.4 | 6.5 | 70 | 50 | 2900 | 11 | 2.5 |

| YG65-250B | 21.6 | 6.0 | 60 | 49 | 2900 | 11 | 2.5 |

| YG65-315 | 25 | 6.94 | 125 | 40 | 2900 | 30 | 2.5 |

| YG65-315A | 23.7 | 6.58 | 113 | 40 | 2900 | 22 | 2.5 |

| YG65-315B | 22.5 | 6.25 | 101 | 39 | 2900 | 18.5 | 2.5 |

| YG65-315C | 20.6 | 5.72 | 85 | 38 | 2900 | 15 | 2.5 |

| YG65-100(I) | 50 | 13.9 | 12.5 | 73 | 2900 | 3 | 3.0 |

| YG65-100(I)A | 44.7 | 12.4 | 10 | 72 | 2900 | 2.2 | 3.0 |

| YG65-125(I) | 50 | 13.9 | 20 | 72.5 | 2900 | 5.5 | 3.0 |

| 型 号 | 流 量Q | 扬程 m | 效率 % | 转速 r/min | 电机功率 KW | 允许汽蚀余量 m | |

| m3/h | l/s | ||||||

| YG65-125(I)A | 45 | 12.5 | 16 | 71 | 2900 | 4 | 3.0 |

| YG65-160(I) | 50 | 13.9 | 32 | 71 | 2900 | 7.5 | 3.0 |

| YG65-160(I)A | 46.7 | 13.0 | 28 | 70 | 2900 | 7.5 | 3.0 |

| YG65-160(I)B | 43.3 | 12.0 | 24 | 69 | 2900 | 5.5 | 3.0 |

| YG65-200(I) | 50 | 13.9 | 50 | 67 | 2900 | 15 | 3.0 |

| YG65-200(I)A | 47 | 13.1 | 44 | 66 | 2900 | 11 | 3.0 |

| YG65-200(I)B | 43.5 | 12.1 | 38 | 65 | 2900 | 7.5 | 3.0 |

| YG65-250(I) | 50 | 13.9 | 80 | 59 | 2900 | 22 | 3.0 |

| YG65-250(I)A | 46.7 | 13.0 | 70 | 59 | 2900 | 18.5 | 3.0 |

| YG65-250(I)B | 43.3 | 12.0 | 60 | 58 | 2900 | 15 | 3.0 |

| YG65-315(I) | 50 | 13.9 | 125 | 54 | 2900 | 37 | 3.0 |

| 65-315(I)A | 46.5 | 12.9 | 110 | 54 | 2900 | 30 | 3.0 |

| YG65-315(I)B | 44.5 | 12.4 | 100 | 53 | 2900 | 30 | 3.0 |

| YG65-315(I)C | 41 | 11.4 | 85 | 51 | 2900 | 22 | 3.0 |

| 80-100 | 50 | 13.9 | 12.5 | 73 | 2900 | 3 | 3.0 |

| YG80-100A | 44.7 | 12.5 | 10 | 72 | 2900 | 2.2 | 3.0 |

| YG80-125 | 50 | 13.9 | 20 | 72.5 | 2900 | 5.5 | 3.0 |

| YG80-125A | 45 | 12.5 | 16 | 71 | 2900 | 4 | 3.0 |

| YG80-160 | 50 | 13.9 | 32 | 71 | 2900 | 7.5 | 3.0 |

| YG80-160A | 46.7 | 13.0 | 28 | 70 | 2900 | 7.5 | 3.0 |

| 80-160B | 43.3 | 12.0 | 24 | 69 | 2900 | 5.5 | 3.0 |

| YG80-200 | 50 | 13.9 | 50 | 67 | 2900 | 15 | 3.0 |

| YG80-200A | 47 | 13.1 | 44 | 66 | 2900 | 11 | 3.0 |

| YG80-200B | 43.5 | 12.1 | 38 | 65 | 2900 | 7.5 | 3.0 |

| YG80-250 | 50 | 13.9 | 80 | 59 | 2900 | 22 | 3.0 |

| YG80-250A | 46.7 | 13.0 | 70 | 59 | 2900 | 18.5 | 3.0 |

| YG80-250B | 43.3 | 12.0 | 60 | 58 | 2900 | 15 | 3.0 |

| YG80-315 | 50 | 13.9 | 125 | 54 | 2900 | 37 | 3.0 |

| YG80-315A | 46.5 | 12.9 | 110 | 54 | 2900 | 30 | 3.0 |

| YG80-315B | 44.5 | 12.4 | 100 | 53 | 2900 | 30 | 3.0 |

| YG80-315C | 41 | 11.4 | 85 | 51 | 2900 | 22 | 3.0 |

| YG80-350 | 50 | 13.9 | 150 | 66 | 2900 | 55 | 3.0 |

| YG80-350A | 44.5 | 12.4 | 142 | 65 | 2900 | 45 | 3.0 |

| YG80-350B | 41 | 11.4 | 135 | 62 | 2900 | 37 | 3.0 |

| YG80-100(I) | 100 | 27.8 | 12.5 | 76 | 2900 | 5.5 | 4.5 |

| YG80-100(I)A | 89 | 24.7 | 10 | 74 | 2900 | 4 | 4.5 |

| YG80-125(I) | 100 | 27.8 | 20 | 76 | 2900 | 11 | 4.5 |

| YG80-125(I)A | 89 | 24.7 | 16 | 74 | 2900 | 7.5 | 4.5 |

| YG80-160(I) | 100 | 27.8 | 32 | 76 | 2900 | 15 | 4.5 |

| 80-160(I)A | 93.5 | 26.0 | 28 | 74 | 2900 | 11 | 4.5 |

| YG80-160(I)B | 86.6 | 24.1 | 24 | 72 | 2900 | 11 | 4.5 |

| 80-200(I) | 100 | 27.8 | 50 | 74 | 2900 | 2 | 4.5 |

| YG80-200(I)A | 93.5 | 26.0 | 44 | 73 | 2900 | 18.5 | 4.5 |

| YG80-200(I)B | 87 | 24.2 | 38 | 71 | 2900 | 15 | 4.5 |

| 80-250(I) | 100 | 27.8 | 80 | 69 | 2900 | 37 | 4.5 |

| YG80-250(I)A | 93.5 | 26.0 | 70 | 68 | 2900 | 30 | 4.5 |

| 80-250(I)B | 87 | 24.2 | 60 | 66 | 2900 | 30 | 4.5 |

| YG80-315(I) | 100 | 27.8 | 125 | 66 | 2900 | 75 | 4.5 |

| 型 号 | 流 量Q | 扬程 m | 效率 % | 转速 r/min | 电机功率 KW | 允许汽蚀余量 m | |

| m3/h | l/s | ||||||

| YG80-315(I)A | 95 | 26.4 | 113 | 66 | 2900 | 55 | 4.0 |

| YG80-315(I)B | 90 | 25 | 101 | 65 | 2900 | 45 | 4.0 |

| YG80-315(I)C | 82 | 22.8 | 85 | 63 | 2900 | 37 | 4.0 |

| YG100-100 | 100 | 27.8 | 12.5 | 76 | 2900 | 5.5 | 4.5 |

| YG100-100A | 89 | 47 | 10 | 74 | 2900 | 4 | 4.5 |

| YG100-125 | 100 | 27.8 | 20 | 76 | 2900 | 11 | 4.5 |

| YG100-125A | 89 | 24.7 | 16 | 74 | 2900 | 7.5 | 4.5 |

| YG100-160 | 100 | 27.8 | 32 | 76 | 2900 | 15 | 4.5 |

| YG100-160A | 93.5 | 26.0 | 28 | 74 | 2900 | 11 | 4.5 |

| YG100-160B | 86.6 | 24.1 | 24 | 72 | 2900 | 11 | 4.5 |

| YG100-200 | 100 | 27.8 | 50 | 74 | 2900 | 22 | 4.0 |

| 100-200A | 93.5 | 26.0 | 44 | 73 | 2900 | 18.5 | 4.0 |

| YG100-200B | 87 | 24.2 | 38 | 71 | 2900 | 15 | 4.0 |

| YG100-250 | 100 | 27.8 | 80 | 69 | 2900 | 37 | 4.0 |

| YG100-250A | 93.5 | 26.0 | 70 | 68 | 2900 | 30 | 4.0 |

| YG100-250B | 87 | 24.2 | 60 | 66 | 2900 | 30 | 4.0 |

| YG100-315 | 100 | 27.8 | 125 | 66 | 2900 | 75 | 4.0 |

| YG100-315A | 95 | 26.4 | 113 | 66 | 2900 | 55 | 4.0 |

| YG100-315B | 90 | 25 | 101 | 65 | 2900 | 45 | 4.0 |

| YG100-315C | 82 | 22.8 | 85 | 63 | 2900 | 37 | 4.0 |

| YG100-100(I) | 160 | 44.4 | 12.5 | 73 | 2900 | 11 | 4.5 |

| YG100-125(I) | 160 | 44.4 | 20 | 74 | 2900 | 15 | 4.5 |

| YG100-125(I)A | 140 | 39 | 17 | 72 | 2900 | 11 | 4.5 |

| YG100-160(I) | 160 | 44.4 | 32 | 32 | 2900 | 22 | 5.6 |

| YG100-160(I)A | 140 | 39 | 28 | 28 | 2900 | 18.5 | 5.0 |

| YG100-200(I) | 100 | 44.4 | 50 | 50 | 2900 | 37 | 5.2 |

| YG100-200(I)A | 140 | 39 | 45 | 45 | 2900 | 30 | 4.5 |

| YG100-200(I)B | 100 | 27.8 | 40 | 40 | 2900 | 22 | 4.5 |

| YG100-250(I) | 160 | 44.4 | 80 | 80 | 2900 | 55 | 4.8 |

| YG100-250(I)A | 140 | 39 | 72 | 72 | 2900 | 45 | 4.5 |

| YG100-250(I)B | 100 | 27.8 | 65 | 65 | 2900 | 37 | 4.5 |

| YG100-350 | 100 | 27.8 | 150 | 150 | 2900 | 90 | 4.0 |

| YG100-350A | 87 | 24.2 | 142 | 142 | 2900 | 75 | 4.0 |

| YG100-350B | 82 | 22.8 | 135 | 135 | 2900 | 55 | 4.0 |

| YG125-100 | 160 | 44.4 | 12.5 | 12.5 | 2900 | 11 | 4.0 |

| YG125-100A | 143 | 39.7 | 10 | 10 | 2900 | 7.5 | 4.0 |

| YG125-125 | 160 | 44.4 | 20 | 20 | 2900 | 15 | 4.0 |

| YG125-125A | 143 | 39.7 | 16 | 16 | 2900 | 11 | 4.0 |

| YG125-160 | 160 | 44.4 | 32 | 32 | 2900 | 22 | 4.0 |

| YG125-160A | 150 | 41.7 | 28 | 28 | 2900 | 18.5 | 4.0 |

| YG125-160B | 138 | 38.3 | 24 | 24 | 2900 | 15 | 4.0 |

| YG125-200 | 160 | 44.4 | 50 | 50 | 2900 | 37 | 5.5 |

| YG125-200A | 150 | 41.7 | 44 | 44 | 2900 | 30 | 5.5 |

| YG125-200B | 138 | 38.3 | 37.5 | 37.5 | 2900 | 22 | 5.5 |

| YG125-250 | 160 | 44.4 | 80 | 80 | 2900 | 55 | 5.0 |

| YG125-250A | 150 | 41.7 | 70 | 70 | 2900 | 45 | 5.5 |

安装使用说明:

1、安装前应检查机组紧固体有无松动现象,泵体流道有无异物堵塞,以免水泵运行时损坏叶轮和泵体。

2、安装时管道重量不应加在水泵上,以免使泵变形。

3、安装时必须拧紧地脚螺栓,以免起动时振动对泵性能的影响。

4、为了维修方便和使用安全,在泵的进出口管路上各安装一只调节阀及在泵出口附近安装一只压力表,以保证在额定扬程和流量范围内运行,确保泵正常运行,延长水泵的使用寿命。

5、安装后拨动泵轴,叶轮应无磨擦声或卡死现象,否则应将泵拆开检查原因。

6、泵分硬性联接安装和柔性联接安装两种(见联接方式)。

(一)运行中的维护

1、进口管道必须充满液体,禁止泵在汽蚀状态下长期运行。

2、定时检查电机电流值,不得超过电机额定电流。

3、泵进行长期运行后,由于机械磨损,使机组噪音及振动增大时,应停车检查,必要时可更换易损件,机组大修期一般为一年。

(二)机械密封维护

1、机械密封润滑应清洁无固体颗粒。

2、严禁机械密封在干磨情况下工作。

3、起动前应先盘动泵(电机)几圈,以免突然起动造成石墨环断裂损坏。

4、密封泄漏允差3滴/分,否则应检修。